No user likes it to open the “black box” reflow soldering system. As a rule, this is associated with maintenance or cleaning measures and therefore also with downtime. In order to minimize this, the reflow systems from SMT Wertheim use the energy-efficient principle of process gas cleaning.

|

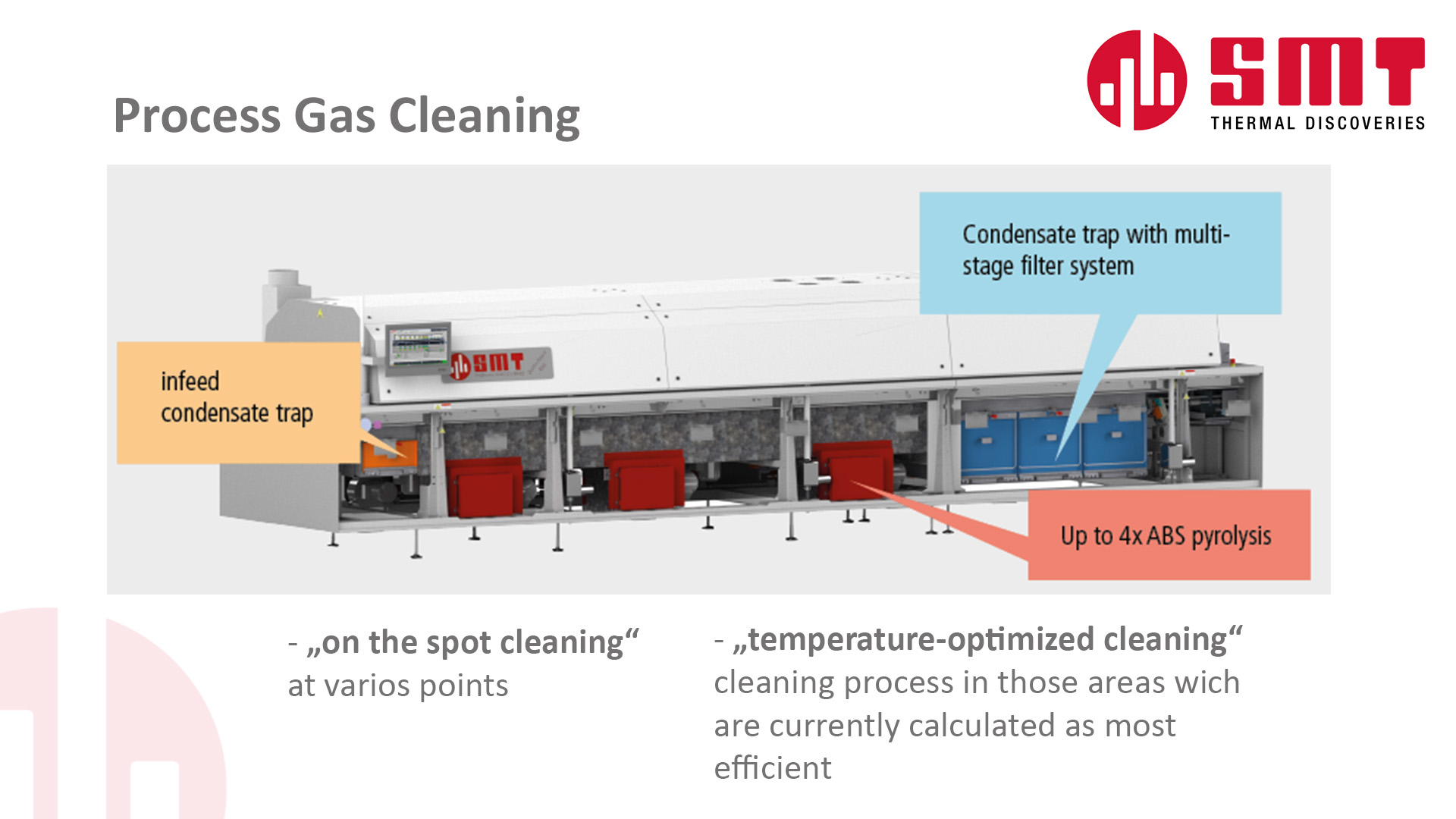

As soon as components entering the process chamber - i.e. in a comparatively cool part of the system - dirt is collected in filters by means of condensation during the preheating process. If necessary, these can be replaced in just a few minutes without tools. The process gas cleaning takes place in the peak zone.

Definition: Catalysis is the change in the kinetics of a chemical reaction using a catalyst.

This change in kinetics activates or accelerates a chemical reaction such as the splitting of long hydrocarbon chains or their oxidation. This process also takes place in the catalytic converter of a car, where most of the exhaust gases from the combustion engine are cleaned in the catalytic converter. The catalytic converter works in the reflow system in a similar way to exhaust gas aftertreatment in the vehicle. The long-chain hydrocarbon chains that are released during the reflow process in the oven condense in colder places in the oven and sometimes cause resinous and oily contamination.

In the soldering system, already heated air is sucked out of the reflow oven (process chamber) by the process gas cleaning system and passed through the catalyst at temperatures of up to 500°C and then returned to the oven (process chamber) in a temperature-regulated manner. The large surface area of the catalyst (granules) coated with precious metals ensures an optimal cleaning effect.

This process not only reduces maintenance intervals and thus downtimes, but the heat energy already introduced directly supports the production process. Process gas cleaning is therefore part of the entire thermal process, including the soldering process.

ABS process gas cleaning in the video

As with the inlet into the system, contamination in the cooling zone is also collected in a condensation process in a multi-stage filter system. These also require no tools and can be replaced in just a few minutes.

Machines - more efficient than ever before

Put to the test - SMT Wertheim examins independent testing by TÜV Süd

Productronica Innovation Award for SMt Wertheim

Watch Global SMT & Packaging's Panel Discussion "Sustainable manufacturing and how to reduce energy and your carbon footprint" with SMT Wertheim's CEO Dr. Christian Ulzhöfer at SMTconnect 2023.

Developments - Innovations & Events with SMT Wertheim